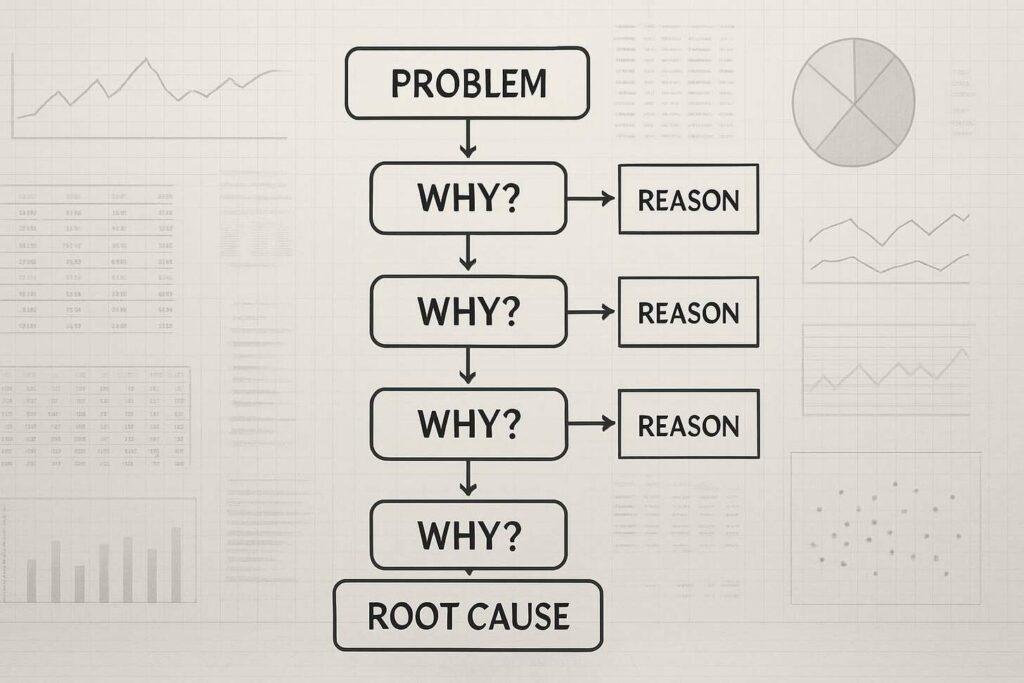

Ever fixed a problem at work, only to see it come back? The 5 Whys mental model was created by Toyota engineer Taiichi Ohno in the 1950s. It’s a simple yet effective tool for finding the real cause.

First used in the Toyota Production System, it changed how the world makes things. Now, it’s used in many fields, like hospitals and software teams. By asking “why” five times, teams find the deep reasons behind problems, not just temporary fixes.

Imagine a leaky roof. Your first thought might be to patch it. But why did it leak? A cracked tile. Why did the tile crack? Poor installation. Each “why” digs deeper, shifting focus from quick fixes to systemic solutions. This approach isn’t just for factories—it works in relationships, projects, or personal goals.

Rooted in simplicity, the 5 Whys technique thrives on curiosity. It replaces blame with clarity, helping teams and individuals grow. By the fifth “why,” you’ll often find answers that surprise you—and create lasting change.

Key Takeaways

- The 5 Whys mental model originated at Toyota to solve production challenges by addressing root causes.

- Replaces surface-level fixes with deeper, systemic solutions.

- Encourages collaborative problem-solving instead of assigning blame.

- Works across personal, professional, and organizational contexts.

- Builds critical thinking skills through structured questioning.

Grasping the Fundamentals of the 5 Whys Mental Model

What if the key to lasting solutions wasn’t complexity but persistent curiosity? This question drove Toyota’s engineers to rethink problem-solving in the 1950s. Their factories became laboratories for innovation, where every malfunction held lessons about human behavior and system design.

Defining the Concept and Its Origins

Taiichi Ohno noticed a pattern: teams often fixed surface issues while ignoring deeper flaws. His method challenged workers to question assumptions five times. Each layer peeled back revealed connections between equipment failures, training gaps, and communication breakdowns. This approach turned repair crews into detectives uncovering hidden truths.

Toyota’s Scientific Approach and Historical Context

The automaker’s production system treated problems as opportunities. Instead of blaming people, they studied why errors occurred. A broken machine wasn’t just repaired—teams traced faults to maintenance schedules, part quality, or workflow design. This three-legged framework transformed factories into learning ecosystems.

By focusing on root cause analysis, Toyota reduced waste and boosted reliability. Their process proved that asking “why” systematically builds smarter solutions. Today, hospitals use it to prevent medical errors, while tech teams apply it to debug code. The method’s power lies in its simplicity—a tool anyone can wield, not just experts.

Data-Driven Insights and Case Studies

Real-world results prove the power of digging deeper. Consider the Lincoln Memorial’s preservation team. They faced rapid stone erosion—a problem initially blamed on aging materials. By asking “why” repeatedly, they uncovered an unexpected chain reaction. Evening lights attracted insects, which drew hungry spiders. Birds feeding on spiders left droppings requiring aggressive cleaners that damaged the stone.

5 Whys Mental Model: Numbers Don’t Lie

Data from Toyota’s factories shows teams using this approach slashed repeat defects by 52% in one year. Across industries, companies report spending 30% less time fixing recurring issues compared to traditional methods. A manufacturing study found 68% of breakdowns traced to systemic causes—not human errors—when teams applied structured questioning.

Beyond Monuments: Everyday Applications

The Lincoln case teaches two lessons. First, seemingly isolated factors often connect in surprising ways. Second, lasting solutions sometimes require multiple fixes—like adjusting lighting schedules and switching cleaning agents. This mirrors findings in healthcare, where root cause analysis reduced medication errors by 41% at Johns Hopkins hospitals.

While effective for clear cause-and-effect relationships, success depends on data quality and team honesty. As shown in structured problem-solving approaches, asking “why” works best when paired with measurable evidence. The method shines brightest when curiosity meets concrete information.

How the 5 Whys Mental Model Differs from Other Root Cause Tools

Many tools try to find the root cause, but the 5 Whys mental model is unique because of its simplicity. Unlike a fishbone diagram (Ishikawa), which looks at many possible causes, or the Pareto chart, which shows the most common causes, the 5 Whys is straightforward. It’s great for problems with a clear cause and effect.

Tools like Failure Mode and Effects Analysis (FMEA) or Six Sigma methods dive deep into statistics. They need training and software. But the 5 Whys only needs curiosity and discipline. This makes it perfect for teams, startups, and families dealing with everyday problems. Its ease of use is a big reason for its lasting success.

Exploring Benefits and Recognizing Limitations

Like a flashlight in a dark room, this approach illuminates paths forward—but only if you know its beam’s reach. Let’s examine where it shines brightest and where shadows might hide unseen issues.

Actionable Takeaways for Everyday Problem Solving

This method trains your mind to pause before jumping to conclusions. When your coffee maker breaks, asking “why” repeatedly might reveal a clogged filter—not a faulty machine. These small times-saving discoveries add up, building sharper analytical muscles.

Teams using the structured questioning method report fewer repeat problems. One teacher shared how tracing classroom disruptions to hunger (not disobedience) led to snack-time adjustments. It works best when causes connect like dominoes—clear and sequential.

Pitfalls and When the Method Might Fall Short

Not all issues follow straight lines. Imagine a delayed project. Was it poor planning? Vendor delays? Team conflicts? The technique might spotlight one factor while missing others. Like using a magnifying glass instead of a wide-angle lens.

Complex relationships between causes demand broader tools. If a hospital’s infection rates rise, focusing only on hand hygiene could overlook equipment sterilization protocols. Stay open to multiple truths—sometimes the fifth “why” is just the beginning.

Use this approach for simple puzzles, not tangled webs. When stakes are high or factors overlap, pair it with other methods. Your sense of when to dig deeper—and when to step back—determines its true value.

When to Use the 5 Whys Mental Model vs. Broader Systems Thinking

When facing linear problems, the 5 Whys method works well. It helps find the root cause of a single issue. But, in complex systems like healthcare or supply chains, things are different. Here, problems often come from many interconnected parts.

To tackle these, use the 5 Whys alongside systems mapping tools, feedback loops, or stakeholder analysis. For instance, long wait times at a hospital might be due to staffing, software issues, or insurance problems. Asking “why” five times might reveal one cause. Yet, without looking at the bigger picture, you might overlook important feedback loops.

5 Whys Examples in the Workplace and Beyond

Let’s walk through two common workplace puzzles where structured questioning shines. One involves tech teams facing unexpected errors, the other a knowledge drain when colleagues leave. Both show how peeling back layers uncovers hidden connections.

When Systems Fail: Tracing Tech Glitches

A payment portal crashed during peak hours. Users saw “transaction failed” messages. The first why revealed database mismatches. Digging deeper, teams discovered security audits delayed updates. The real issue? Developers and admins used different tracking tools. Fixing it required aligning workflows across groups.

When People Leave: Protecting Institutional Knowledge

A developer’s exit left projects stalled. Initial questions focused on missing documentation. The fifth why exposed infrequent peer reviews. While better file storage helped short-term, the method missed compensation gaps affecting retention. Quick fixes matter, but lasting solutions need broader views.

| Scenario | Immediate Fix | Root Cause |

|---|---|---|

| Database errors | Field alignment | Team communication gaps |

| Knowledge loss | Documentation drive | Irregular skill-sharing practices |

| User login failures | Password reset | Outdated authentication protocols |

These examples teach three lessons. First, technical work often masks human factors. Second, asking why in order builds shared understanding. Third, while the method spots urgent fixes, pairing it with other tools addresses deeper cultural issues.

Why the 5 Whys Mental Model Works in Lean and Agile Environments

The 5 Whys method is a great fit for Lean, Agile, and DevOps cultures. It helps teams improve without wasting time. In Lean manufacturing, it spots waste and cuts downtime.

In Agile retrospectives, it helps teams look beyond the surface. They find the real reasons for sprint problems. This way, they can improve more effectively.

For instance, a DevOps team might use 5 Whys to solve deployment errors. They start with build scripts and find missing environment variables. This method is quick and doesn’t slow down work.

Implementing the 5 Whys Mental Model For Continuous Improvement

True progress begins when we stop putting out fires and start finding spark sources. Effective problem-solving requires equal parts curiosity and structure—like peeling an onion layer by layer until tears reveal truth.

Strategies for Effective Root Cause Analysis

Start by gathering a group with varied perspectives—engineers, frontline staff, and end-users. Define the issue clearly: “Customer complaints rose 40% last quarter” beats vague statements. First why might point to delayed shipments, but keep digging.

Link each answer to the next question like train cars. If packaging errors surface, ask what factors allowed mistakes. Avoid blaming warehouse teams—instead, examine training materials or labeling systems. This thinking shift turns finger-pointing into system upgrades.

Proactive Measures and Iterative Problem Solving

Treat solutions as prototypes, not final products. When a software bug recurs after fixes, revisit your analysis. Maybe the fifth “why” initially pointed to code errors, but deeper dives reveal integration gaps with new APIs.

Schedule monthly reviews of resolved issues. Track whether causes stay addressed or mutate. Pair this method with fishbone diagrams when multiple factors intertwine. Remember—complex puzzles need multiple tools.

Build it into team rituals. Start retrospectives by asking “What small fire did we extinguish this month?” Then explore its origins. Over time, this process becomes second nature—transforming reactive teams into prevention experts.

Conclusion

The 5 Whys mental model proves that complexity isn’t always required to solve recurring issues. By repeatedly asking “why,” individuals and teams unlock patterns that traditional methods often overlook. While it works best for linear problems, pairing it with broader tools extends its value in complex systems.

From Toyota assembly lines to healthcare quality teams and Agile product squads, this method continues to fuel smarter decisions and long-term change. Its low barrier to entry makes it a powerful first step toward continuous improvement.

Practice it often, use it wisely, and let curiosity—not just urgency—guide your problem-solving journey.

Think of this method as your first flashlight in a dark room—it illuminates immediate paths but may miss corners.

Pair it with other tools when dealing with intertwined factors like team dynamics or technical dependencies. Success comes from knowing when to dig deeper and when to zoom out.

Remember, the goal isn’t perfection—it’s building adaptable thinking skills for life’s evolving challenges.